Machinery

Spare Parts

Know-How Process

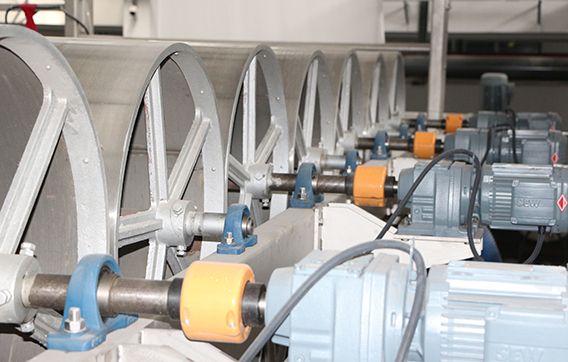

CTMTC- LMH Has Mature Technology And Experience On Finishing & Dyeing Machine

As your reliable supplier, CTMTC will produce highest quality Machinery to offer you the best dyeing fabric

Open Width Finishing & Dyeing Range

The continuous desizing, scouring and bleaching process allows to remove the size, to degrade the waxes and natural fats which are contained in the natural cotton, and to oxidize the chromophores molecules. This Pretreatment proses is the heart of textile, which makes the subsequent dyeing and soften processes easy. CTMTC technology gives a wide range of possibilities, tailoring the preparation range according to their individual specification.

CTMTC- LMH Series

Specializes in the continuous finishing treatment of woven and knitted fabrics

CLEVER FEATURES

Highlights of CTMTC-HTHI-1 Spunlace Line

- High production speed;

- Enhanced production capacity;

- Non-stop production;

- Robust construction of the entire equipment;

- High end continuous production due to splicing systems;

- Reduced maintenance downtime for higher efficiency;

- Energy efficiency for a better carbon footprint;

- Easy to operate in all functions of the line; Quality control system included;

- Quick delivery and assembly of the line;

Your CTMTC expert

Do you have any questions?

I am gladly to there for your

Mao Yuping

medium

medium Inquiry

Inquiry