CTMTC

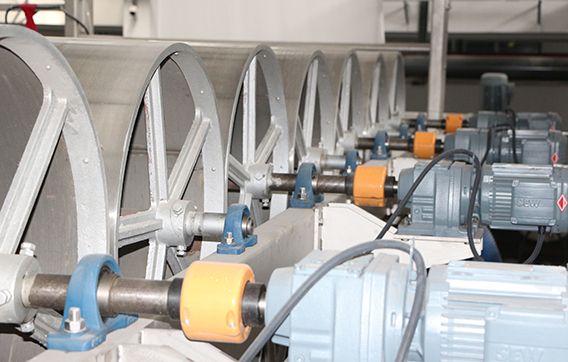

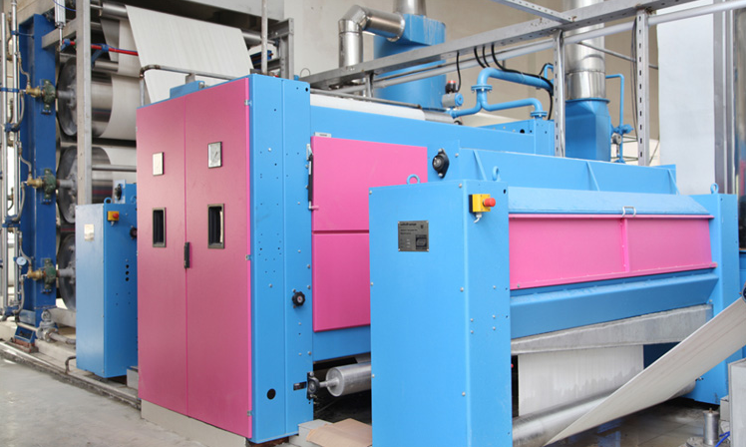

Complete Open Width Finishing and Dyeing Machinery Solution

MANUFACTURING HISTORY

Over 40 YearsWORLD MARKET

Supplied Over 10 CountriesCTMTC- Has Mature Technology And Experience On Continuous Dyeing Machine

As your reliable supplier, CTMTC will produce highest quality Machinery to offer you the best dyeing machine

CLEVER FEATURES

Highlights of CTMTC-Finishing and Dyeing Line

•High production speed;

•Enhanced production capacity;

•Non-stop production;

•Robust construction of the entire equipment;

•High end continuous production due to splicing systems;

•Reduced maintenance downtime for higher efficiency;

•Energy efficiency for a better carbon footprint;

•Easy to operate in all functions of the line; Quality control system included;

•Quick delivery and assembly of the line;

Your CTMTC expert

Do you have any questions?

I am gladly to there for your

Mao Yuping

Leave Your Message:

Write your message here and send it to us.

Download As PDF

Download As PDF medium

medium Inquiry

Inquiry