CTMTC Stenter

Leading brand in the field of textile stenter and heat setting in ChinaCTMTC

Has the mature stenter solution to offer textile and technical applications

As your reliable supplier, CTMTC will provide high quality stenter/tenter machinery to stentering, drying, heat-setting of your fabric

Stenter / tenter

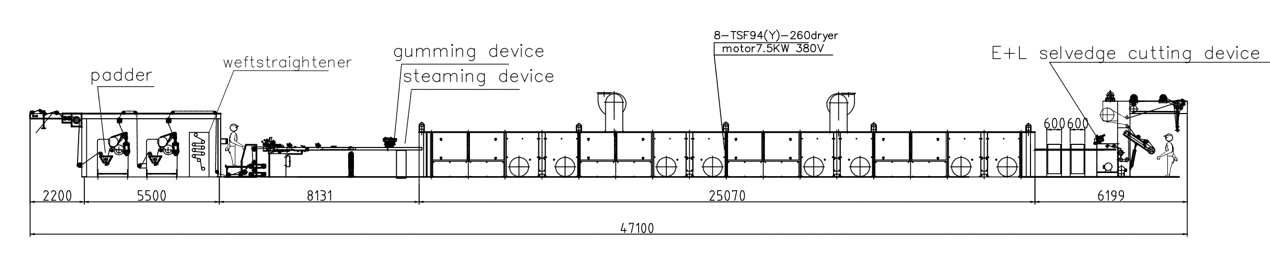

Stenter is a specialist oven used in the textile industry for drying and heat-treating fabric after wet processing. It is the most expensive and important fabric drying and finishing machine. During working, it carries fabric from one point to another continuously in open width with precise width control. There are two types of stenters, pin stenters and clip stenters, depending on the means of holding the fabric onto the chains.

Manufacturing History

Over 40 years

World

market

Supplied over 10 countries

The most important data at a glance

| Machine Name | Stenter/tenter |

| Brand | CTMTC |

| Original | China |

| Application | Multi purpose stenter for drying, heat setting, width setting and curing of various types of fabric and nonwovens |

| Drive | Left, Right |

| Width | 1800-5500 |

| Mechanical Speed | 1800-3600mm |

| Minimum Working Width | 450mm |

| Heat | Gas direct, gas indirect, thermal oil, steam, electricity |

| Chamber | 3-12 chambers |

Your Benefits

First &Complete Stenter Machine

Since many decades,CTMTC always stand for offering you highest quality and performance stenters/tenters, all stenter/tenter frames we offered are producing sustainably and energy-efficiently. CTMTC will always be your first choice on the stenter machine.

With good performance stenter system, we can guarantee the fabric drying result based on the special design on every part of our machine, including the tension unit, temperature control unit, heating system , speed control unit and so on.Based on CTMTC 40 years stenter/ tenter production experience,with choice of CTMTC machine, your stenter machine will be the highest level of the world,No matter the big system like heating system,split-flow air circulation system, temperature distribution,but the process control system ,including electrical control system, automatic and tension system,even small parts which you may rarely notice like chains,chain rails, pin bar carriers and clips,

every part of the machine is the produced and equipped with best material and best process. And the special design in the control system will make sure the heat setting result and energy saving the same time.The perfect stenter/tenter result will strength your competition in the market on both capacity and drying effort.

Outstanding Quality With Higher Efficiency

Our core competence is system designed for the production of high quality standard drying fabric. Whether knitted fabric, woven fabric, nonwovens, technical textiles, carpets, PVC floor coverings and other web-shaped materials, we will give impetus to your success on high quality standard fabric.

The complete CTMTC stenter/tenter machine using high quality materials and accessories. padder, weft straightener, overfeeding devices, selvedge uncurling unit, edge controlling unit, air burning and cooling system, batching system, all of the parts are professional and with famous brand, your stenter machine will make sure you can get outstanding stenter/tenter result and high efficiency . The length and width of the fabric after stenter/tenter is just same as pre-determine dimensions, and also have good results on drying and heat-settingafter wet processing.

Cost-efficient On One Time Investment & Manufacturing & Maintenance

With Adoption of CTMTC Stenter Machine, your initial investment on machinery will save a lot, and your cash flow will be much healthier, more finance can be invested on business expanding, research development, and labor training.

To guarantee your competition advantage, CTMTC adopts optimized production process, efficient system, sustainable technologies. The complete automation and administration guarantee an exactly reproducible finishing result. That’s also make sure your stenter machine will with very low specific energy consumption. And automation and digital system make sure the machine running constantly and smoothly, less labor needed and cost.

The extremely robust parts will make sure the machine need minimum maintenance cost. One-on-one technician and service manage to offer support and lifelong spare parts service to make sure your machine always under a secure state, you will no need to worry about the maintenance at all.

Strong Design & Technician Support

Your CTMTC expert

Do you have any questions?

I am glad to be there for you

Mao Yuping

CTMTC

Download

Download medium

medium Inquiry

Inquiry