News

-

Oerlikon Barmag, Germany, celebrates its 100th anniversary

Today, the leading manufacturer of man-made fiber spinning systems and texturing machines from Remscheid promotes technological advances in this area. There will be more innovation focused on sustainability and digitalization in the future. Barmer Maschinenfabrik Aktiengesellschaft (Barmag) was f...Read more -

Polyester filament yarn market to reach $174.7 billion by 2032

Fact.MR’s latest research on the global polyester yarn market provides a detailed analysis of various drivers, trends and opportunities from 2022 to 2032. In addition, it details types, yarn types, dyeing processes and regions. The global polyester filament yarn market is expected to grow a...Read more -

spunlace line in Magiran

Graz, Austria – January 24, 2022 Uzbek cotton specialist Texygen Textile LLC has he first spunlace production line installed in Uzbekistan. The equipment will process high quality cotton fiber in a fully integrated line from bleaching to winding. With this new line, Texygen Textile will be able ...Read more -

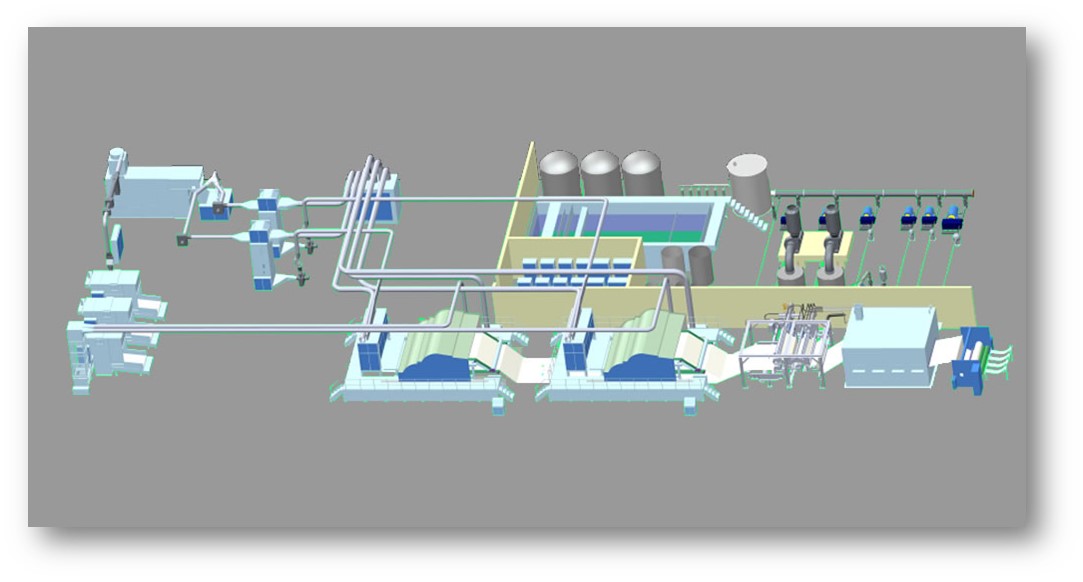

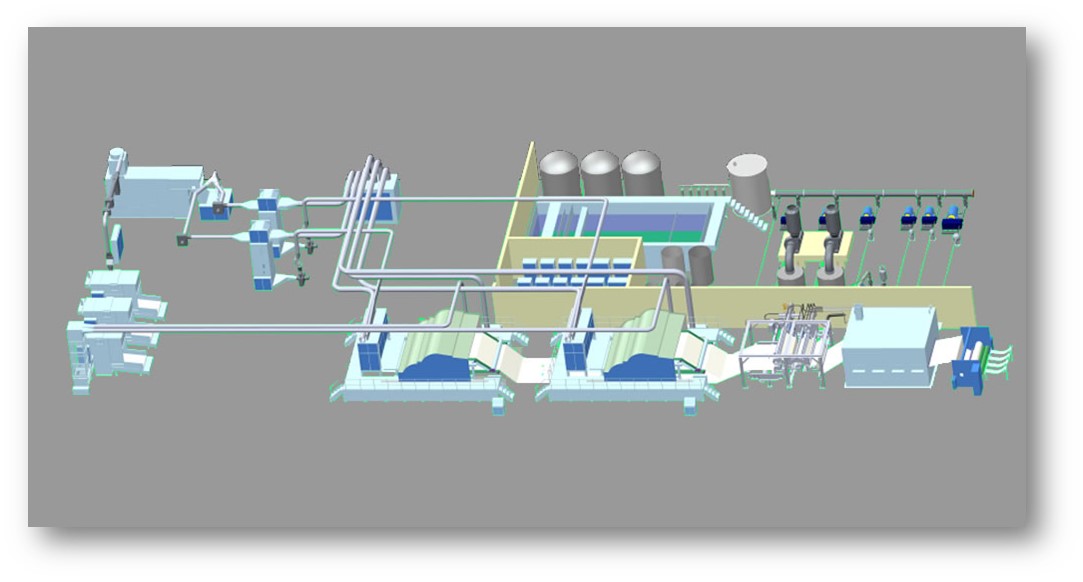

Spunlace Process From CTMTC HTHI

Hygiene Spunlace Line (Dry-laid by Roller Carding) ——2 Carding Parallel Line This Line is mainly used for Wet tissue, dry tissue, wiping material, with GSM 30-80gsm, Max. Capacity is around 25-35 tons per day; Leather Substrate Spunlace Line (Dry-laid by Roller Carding) ——...Read more -

BB Engineering Unveils First Bottle-to-Poly Line at Open House Event

The visitors saw what the company calls the world’s first VarioFil R+ bottle spinning line in action. Last week, more than 120 customers from all over the world were invited by BB Engineering (BBE) to the presentation of the new machine at an open house event at its plant in Remscheid, Germ...Read more -

Indian Yarn Manufacturer Begin FDY Recycled Polyester Yarns

Indian yarn manufacturer Polygenta specializes in sustainable recycled yarns and has recently started production of FDY recycled polyester yarns at its Nasik factory. The yarn is produced using a combination of perPETual Global Technologies’ patented chemical processing technology and Oerli...Read more

Leave Your Message:

Write your message here and send it to us.