-

Quenching System For POY/FDY Production

Quenching system is import to filament lines, to confirm if the quenching system is functioning effectively in filament yarn production, you can consider the following factors: Filament Cooling: Check if the quenching system is providing sufficient and consistent cooling to the filaments. The fi...Read more -

Temperature Control During the POY/FDY Process

Controlling the temperature during the POY (Partially Oriented Yarn) production process is crucial to ensure the desired quality and properties of the yarn. The specific temperature control methods can vary depending on the equipment and processes used, but here are some general guidelines: Prehe...Read more -

The Process Difference on POY Yarn and FDY Yarn

The main process difference between POY (Partially Oriented Yarn) and FDY (Fully Drawn Yarn) lies in the stretching or drawing stage during their production. Here’s a brief overview of the processes for both types of yarn: POY (Partially Oriented Yarn) Process: Melting and Extrusion: The p...Read more -

Basic Inforamtion of Filament Yarn

What is Filament? Filament yarn is a type of yarn that is made up of continuous, long fibers or filaments. Unlike spun yarn, which is made by twisting shorter fibers together, filament yarn is created by extruding long strands of fibers from a spinneret, a device that resembles a shower head with...Read more -

Process of Recycled PSF Production Line for 3D hollow fiber

In the spinning plant, the bottle flakes are melted in extruders, and spun into tows. The melt coming out of the homogenizer goes into spin beam in which the specially-designed distribution piping system guarantees the same dwell time for the melt to reach each spinning position. After passing th...Read more -

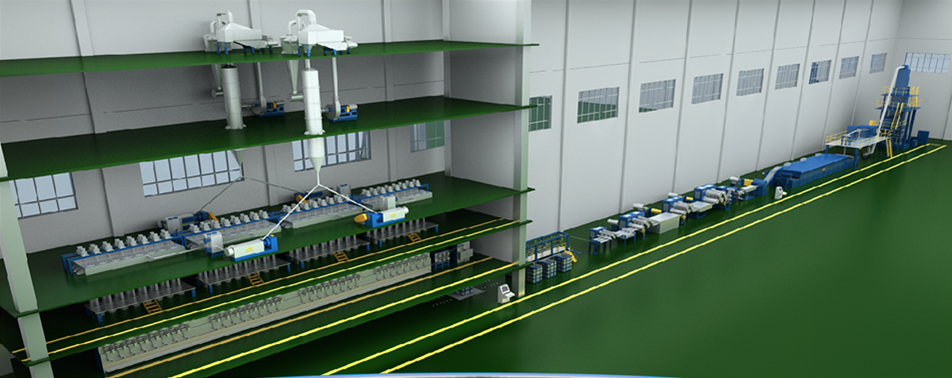

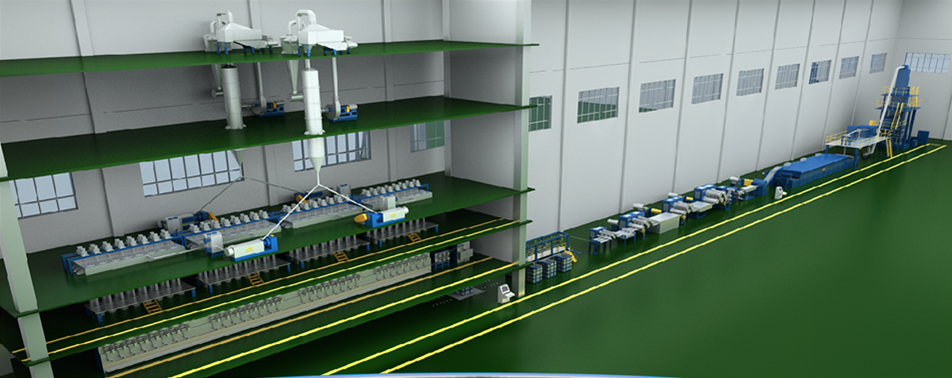

Building Design of the PSF production line

PSF Production line separate into two steps: One is the spinning line,Another one is fiber line (drawing line) For example, for spinning line with 20 positions with 80TPD, the spinning building dimension is about 42 m* 24 m *33 m (L*W*H) including dryer and homogenizer. The raw wet flakes feedin...Read more

Leave Your Message:

Write your message here and send it to us.