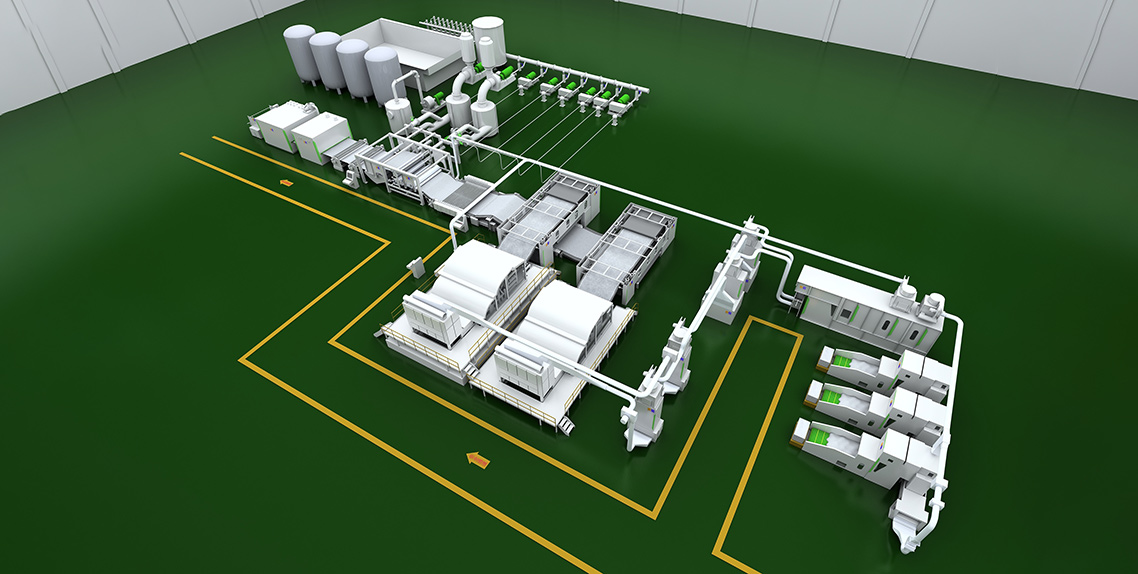

CTMTC Parallel Spunlaced Production Line

Solution for wipes, medical, hygieneWith social progress, people requires optimal feeling in personal care

CTMTC consistently produce high quality machinery, to manufacture personal care production that help many people to feel more comfortable and secure and making you a reliable supplier.

The Most Important Data At A Glance

| Production | High Speed Direct Layer Spunlaced Line |

| Raw materials | polyester, viscose, pure cotton, tencel, bamboo fiber, modal, chitin, etc. |

| Fabrics | 20-120gsm |

| Lines Widths | Up to 3500 |

| Production Speed | Up to 300m/min |

| Capacity Per Day | Up to 50TPD |

| Uptime Efficiency | 90% |

| Space(Max) (L*W*H) | 30m* 90m *7m |

| Extra Features | Low maintenance, Low Downtimes |

Production History

24 YEARS +

Market Share

70%+

RUNNING LINES

300 lINES+

Main Device

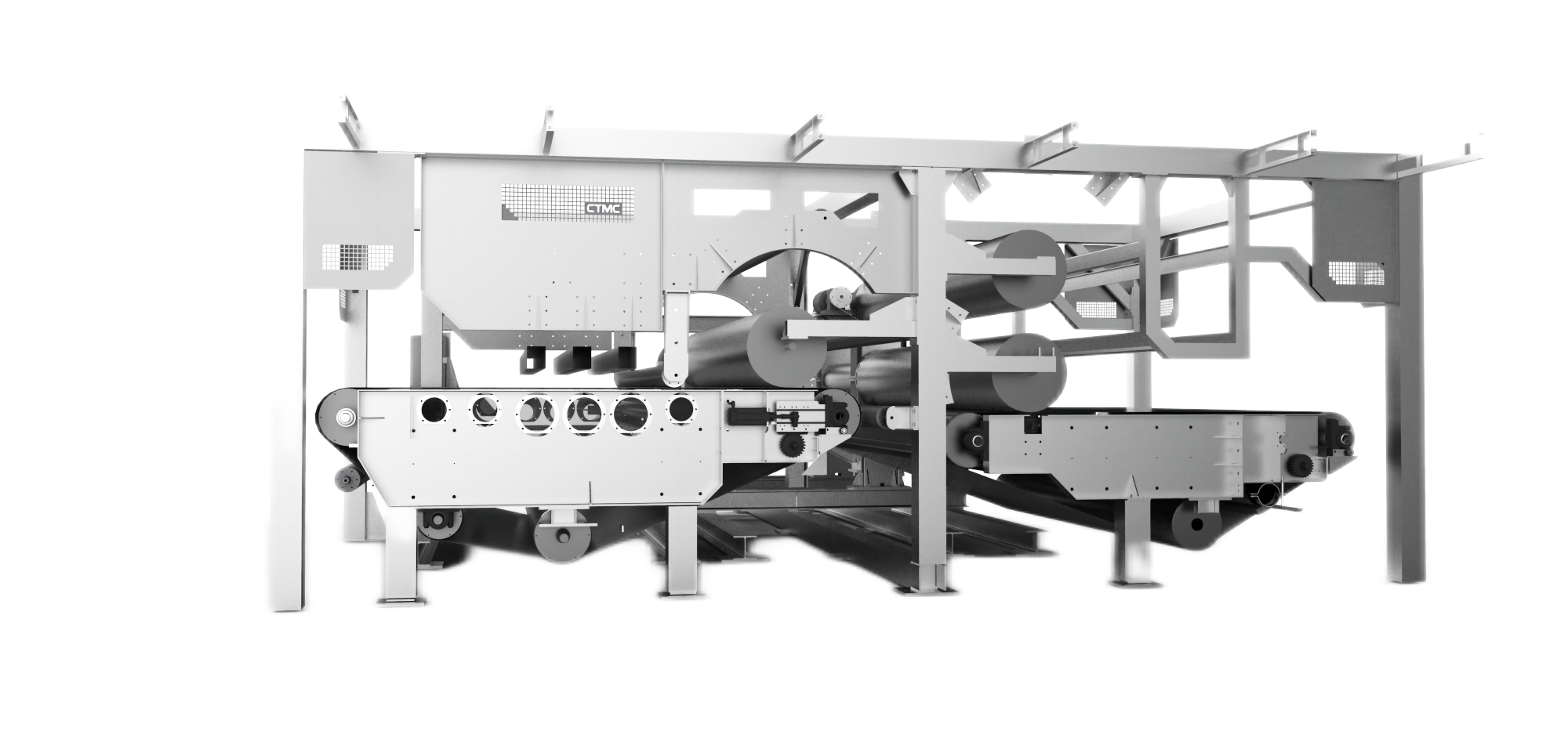

Carding

- The flat carding machine has many combing points, space between combing elements is small, fiber web is even. the carding area forms a confined space, with less flying on the spot, a clean working environment. It is suitable for combing such as raw cotton, bleached cotton, bamboo diber, modal and tencel fiber.

- Type: 1-licker-in, 3-licker-in

- Width: 1500, 1800

- Revolving flat type: aluminum alloy, cogged belt drive Web

- g/m2:15-30

- Speed:100m/min

Main Device

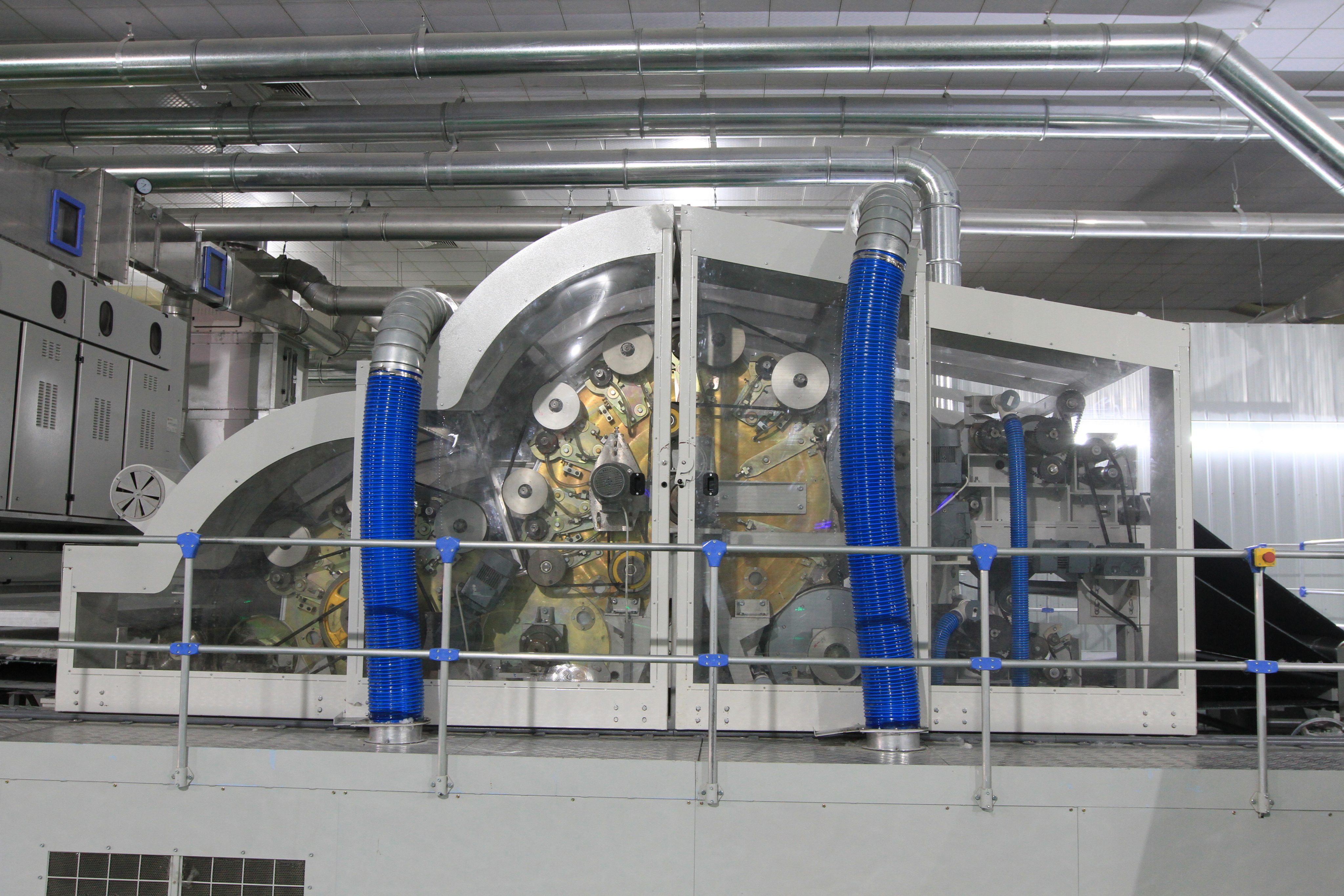

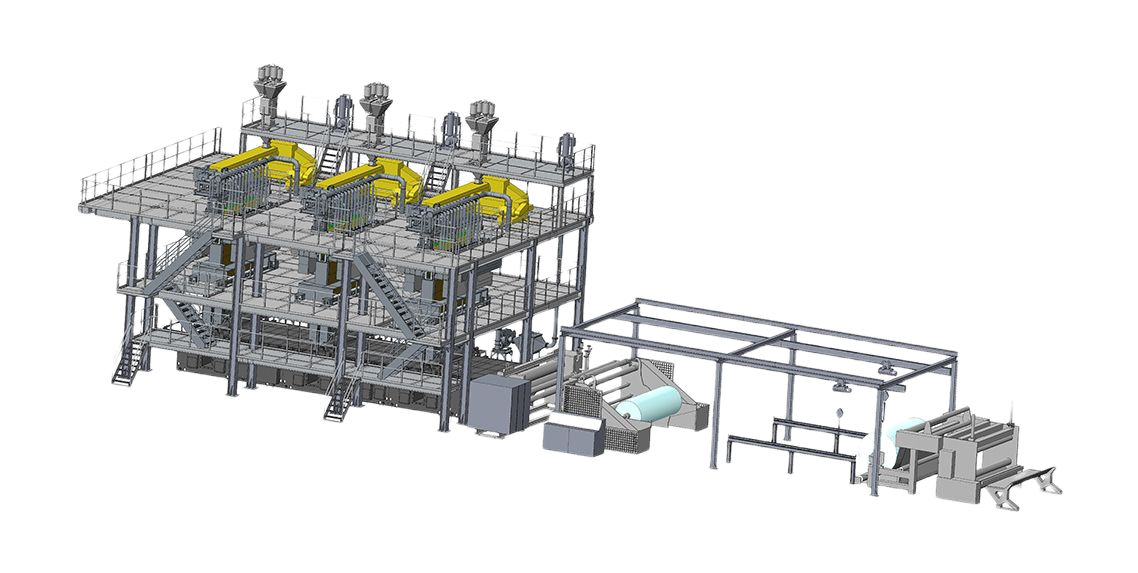

Spun-laced Machine

- Modular design meet varieties of requirement applicable to various process such as tabby, perforation, jacquard, composite etc

- Direct-axis suction roller with higher through hole ration whole slit-way water flow channel

- Injection pressure up to 50 MPa

- Width: 3.5m, 2.5m, 1.8m

- Max GSM: 200g/㎡

- Speed: 300m/min

- Max hydraulic pressure: 400bar Function modular

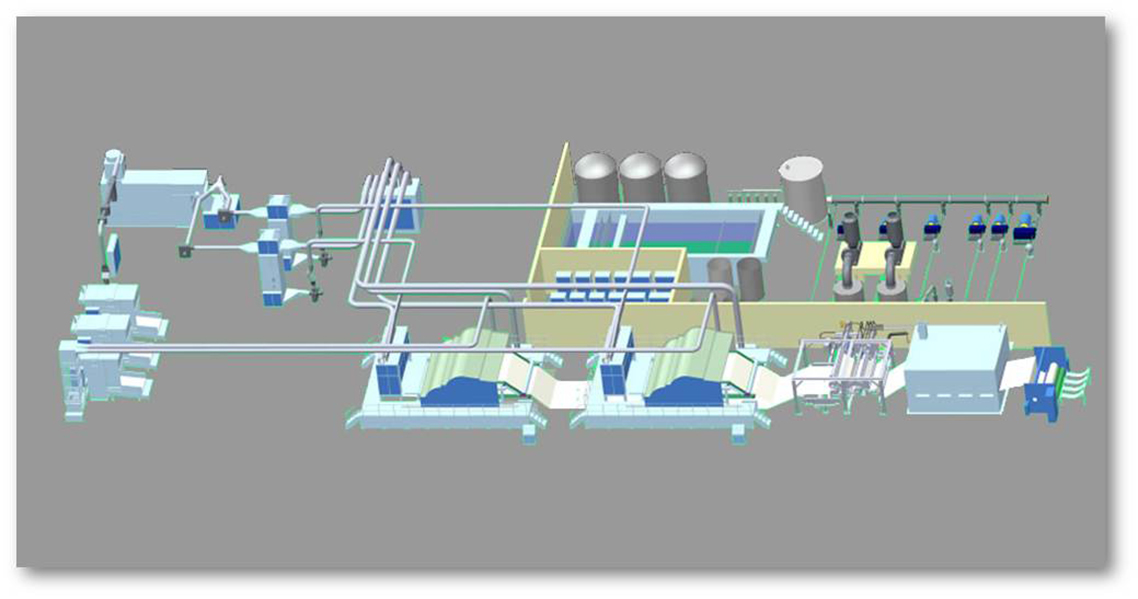

Main Device

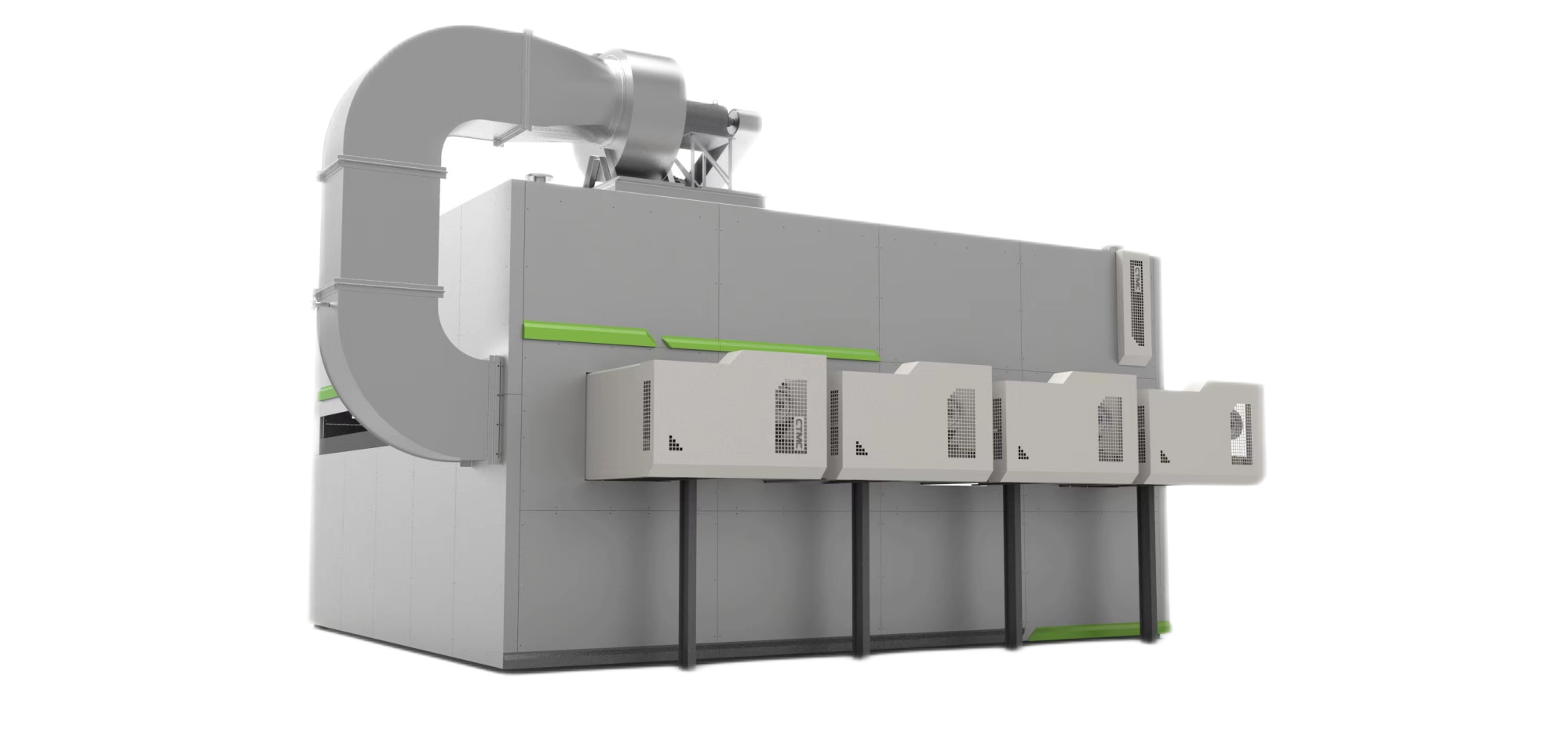

Dryer

- Hot air through drum drying, diameter of drum is 1400mm,1900mm

- many types of heating methods, oil heating saturated steam, natural gas

- Whole machine has good sealing performance, high-efficiency circulating fan, strong suction force, large air volume and high hot air utilization;

- Inside wall of the chamber and all the parts in contact with the hot air are made of 304 stainless steel;

- Modular design to realize fast combination of drum quantity, heating mode and working width.

Main Device

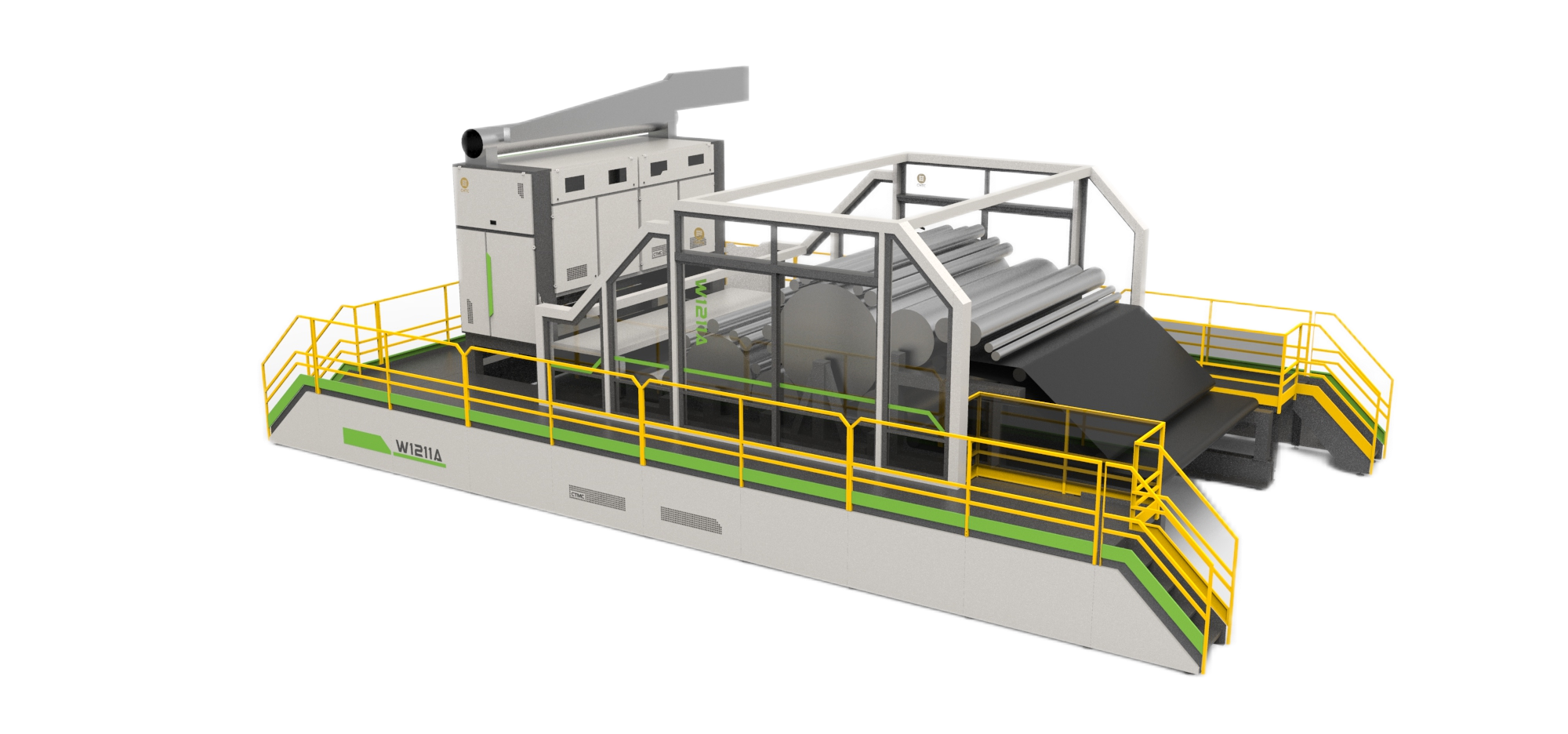

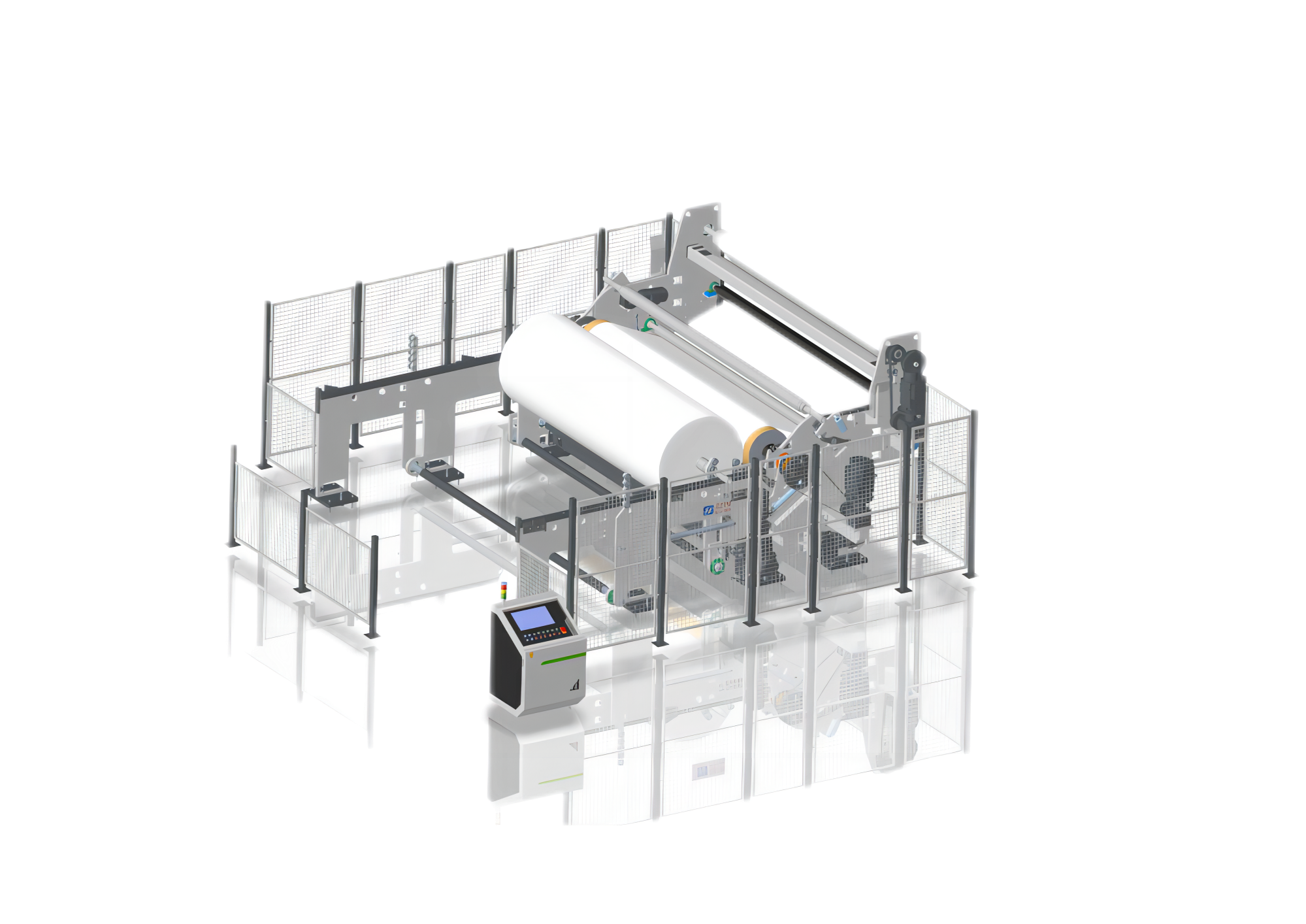

Winder

- Combining surface drive with pressure to achieve optimum hardness of finished roll, tension is adjust precisely on different materials.

- Integrated cross-cutting and roll exchange system ensure roll exchange automatically without speed reduction. efficiency of the whole line is improved;

- Equipped with the shaft-back automatically system to reduce labor intensity of workers;

- Meet sample proofing of small rolls, reduce consumption of raw material for proofing and cost saving.

Clever Features

Highlights of CTMTC Spunlace Line

- Higher production speed , and non stop production will make sure higher efficiency and capacity;

- Better equipment quality, with robust construction, splicing system, carbon footprint,quality control system;

- Better service,with quick delivery and assembly, reduced maintenance downtime, easy to operate.

Service and Support

- As long as you choose CTMTC production, you will get full service and support;

- There will be professional desigen and reliable feasibility report for you to make final decision;

- We are at your side support, and will help you achieve long time production success with existing equipment ,and expanding your business with maximum efficiency;

- All the solution we offered are customer-made, we will offer professional design knowledge and excellent manufacturing quality.

Video

Your CTMTC expert

Do you have any questions?

I am glad to be there for you

Michael Shi

CTMTC

Leave Your Message:

Write your message here and send it to us.

Download

Download medium

medium Inquiry

Inquiry