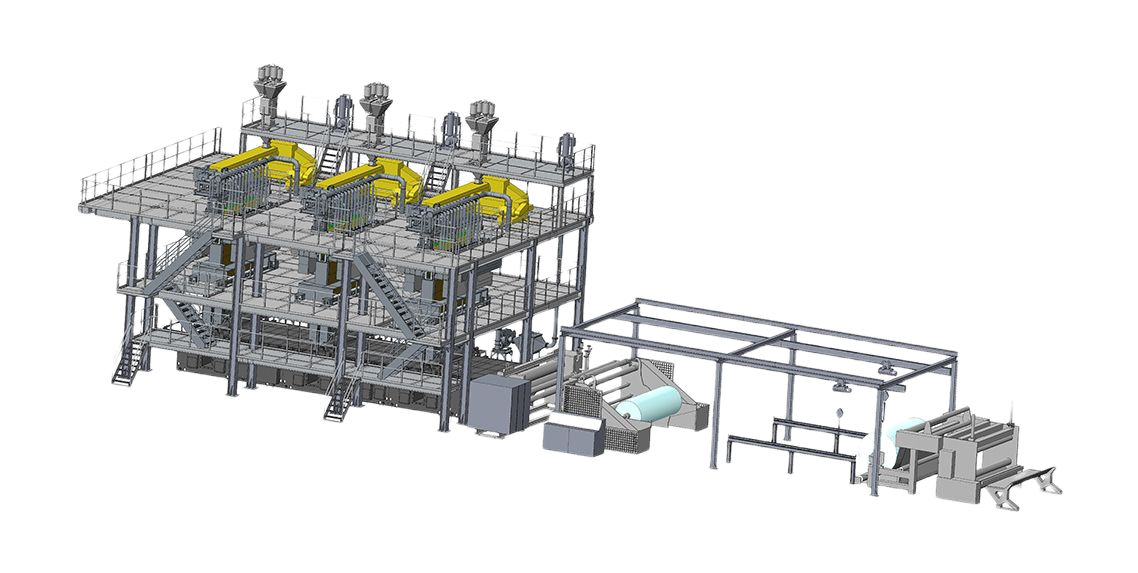

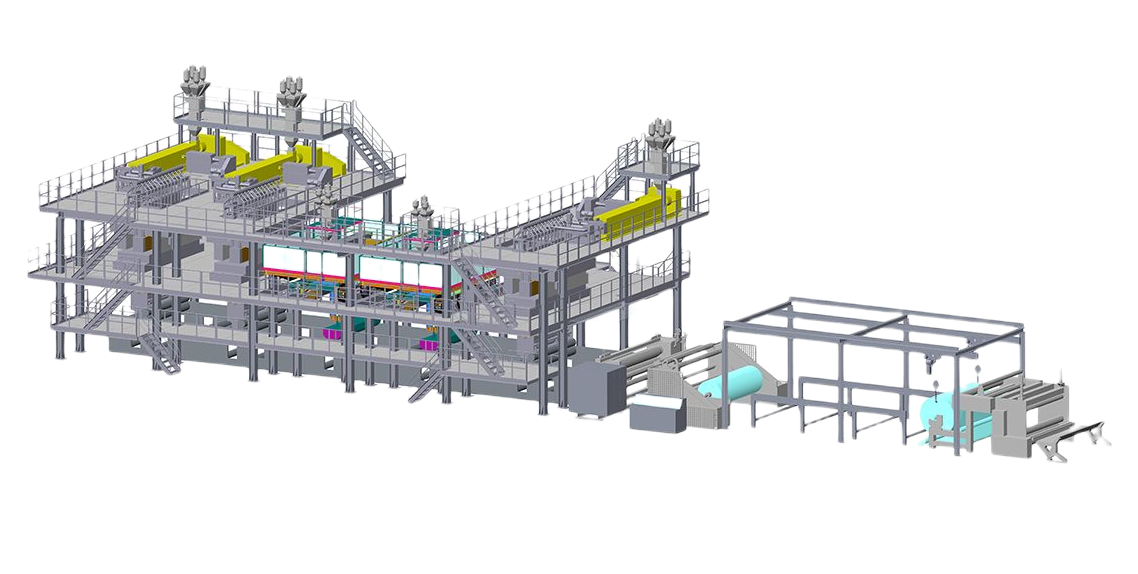

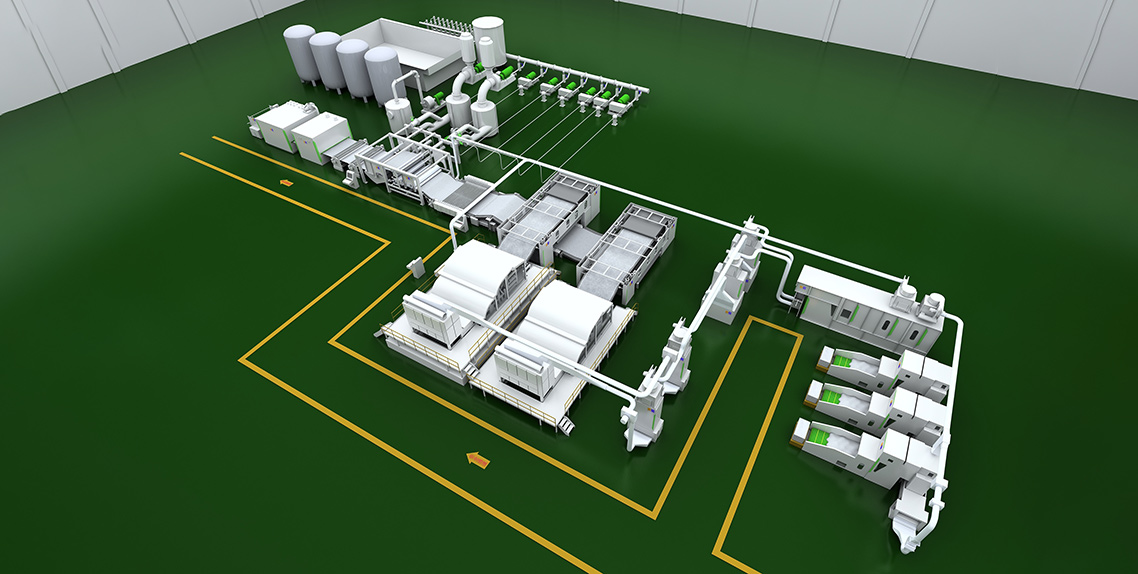

CTMTC Wet-Laid Spunlaced Nonwoven Line

Solution for dispersible fabric,flushable wipesCTMTC

consistently produce high quality machinery, to manufacture personal care production that help many people to feel more comfortable and secure and making you a reliable supplier.

The most important data at a glance

| Production | Wet Laid Spunlaced Line |

| Raw materials | Pulp, PSF , Viscose , PP , Silk , Tencel , etc. |

| Applications | Wipe,Rages,Toilet Tissues, Flush able Fabric,Napkins, Diapers, Towels, Bed Sheets, etc |

| Fabrics | 30-100gsm |

| Lines widths | Up to 3500 |

| OutPut | More than 20000Tons/year |

| Energy Consumption per Ton | 1. Water: 6-10 Ton2. Electricity: 1500-2000 kwh3. Steam:3-5Ton |

| Extra features | Low maintenance |

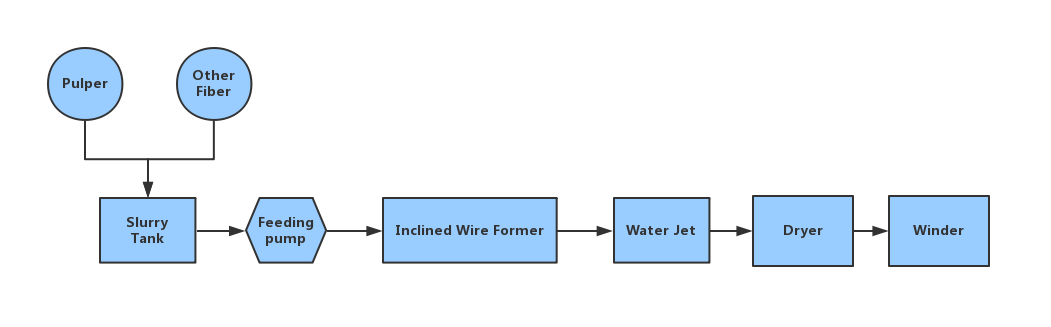

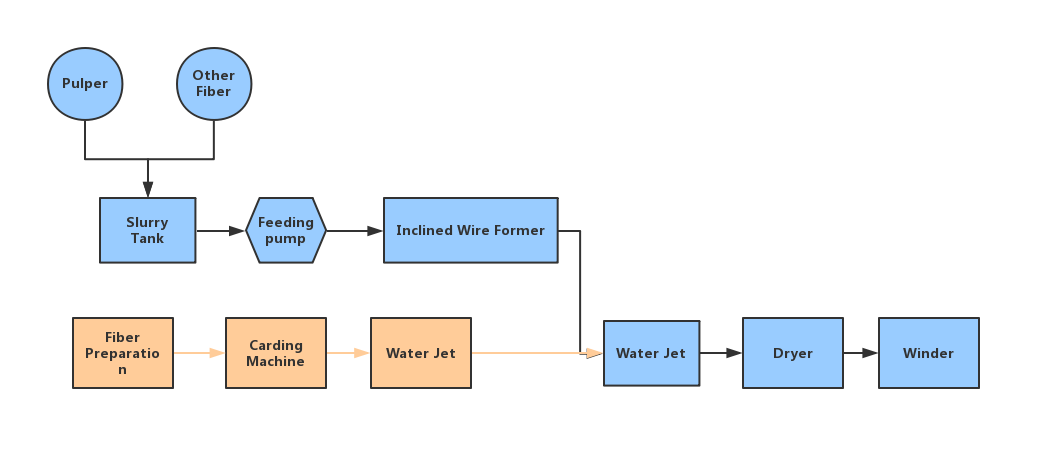

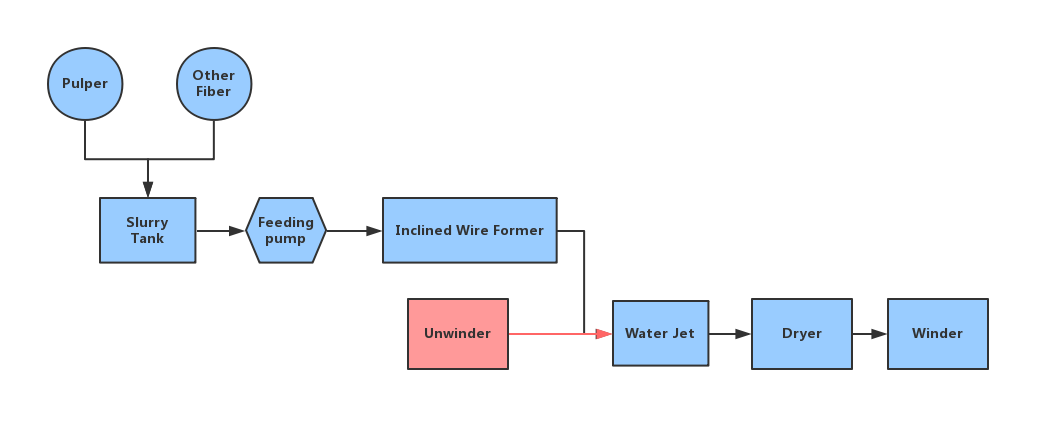

Process Flow For Wet-Laid/Spunlace Nonwovens

No carding machine, all material comes from wet-laid

One layer comes from Carding + the other layer comes from wet-laid

Unwinding PP layer + layer comes from wet-laid

Production History

24 YEARS +

Market Share

70%+

RUNNING LINES

300 LINES+

Clever Features

Highlights of CTMTC Wet Laid Spunlace Nonwoven

- High production speed

- Enhanced production capacity

- Non-stop production

- Robust construction of the entire equipment

- High end continuous production due to splicing systems

- Reduced maintenance downtime for higher efficiency

- Energy efficiency for a better carbon footprint

- Easy to operate in all functions of the line

- Quality control system included

- Quick delivery and assembly of the line

Your Benefit

High Level Nonwoven Production Solution

With years of experience and comprehensive textile competence, CTMTC built up a reliable process solution on both machinery and process. You will get innovative and reliable products on all your demands, no matter machinery, spare parts or, process.

Well-known Brand of Key Parts Escort Nonwoven Production Line

As the leading manufacturer in Spun Lace Machine, CTMTC cooperate with world famous brand on key parts to make sure top-level nonwoven fabric quality and energy saving.

Individualized Design & Technician Support

Including: Feasibility study report/Professional design/High quality machinery /Installation and commission /Stuff training and process support

Out Standing Nonwoven Fabric Appearance For Your Winning In The Market

With adoption of CTMTC Spun lace production line, you can receive Good cost performance/Optimized production processes/Running constantly and smoothly /Minimum maintenance cost/One-on-one technician and service /Longtime spare parts service

Service and Support

- Full CTMTC service and support, optionally for entire product life cycle

- We help you achieve long-term production success and support you in expanding your business with existing equipment, we are at your side support, advice, know-how and service-in person.

- Professional design and reliable feasibility report for your decision

- The solutions are designed for customer-made, maximum efficiency, have numerous optional possibilities with professional design knowledge and excellent manufacturing quality.

Video

Your CTMTC expert

Do you have any questions?

I am glad to be there for you

Michael Shi

CTMTC

Download

Download medium

medium Inquiry

Inquiry