-

Advantage of CTMTC-HTHI FDY/POY Filament Equipment

CTMTC-HTHI has began the produce of POY/FDY machine since 30 years ago, CTMTC-HTHI is famous and widly used in domestic market. 1) The first domestic manufacturer use contact roller, and other manufacturers began to use CR in 2015; 2) The first manufacturer use 1680 winder in China; 3) The first ...Read more -

Advantage of CTMTC-HTHI POY/FDY Filament Winder Equipment

CTMTC-HTHI Filament Winder has into domestic market since Year 2000, so we have long history in winder production: 1) The first domestic manufacturer use contact roller, and other manufacturers began to use CR in 2015; 2) the first manufacturer use 1680 winder in China; 3) The first manufacturer ...Read more -

Introduction of PSF Production Machinery -2

Creel The tow creel is arranged for 4 rows .Including: two rows put into using, other two for preparing. Tow guide frame and DIP bath The tows from tow creel guided by tow guide frame and passed through DIP bath .Split tow sheets evenly with certain width and thickness for next drawing process. D...Read more -

Introduction of PSF Production Machinery -1

Heated and dried Main purpose to remove the moisture from the raw material and also increase the softening temperature of raw material. Screw extruder For melting and mixing the PET bottle flakes or chips from hopper after being heated and dried. Diameter series of our screws: Ф120/Ф150/Ф160/Ф1...Read more -

Polyester Staple Fiber Production Line

Polyester Staple Fiber Production Line History The PSF machinery were manufactured in early 1970s. In middle 1990s, we began to research and develop 100t/d production line; and in 2002, this line was put into production. Developed the whole set of 120t/d production line in 2003. From 2005 to 201...Read more -

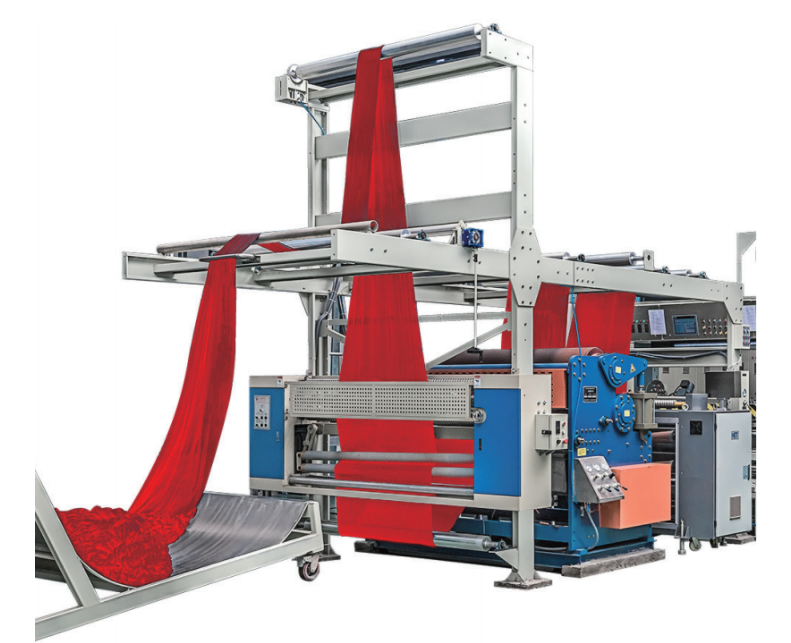

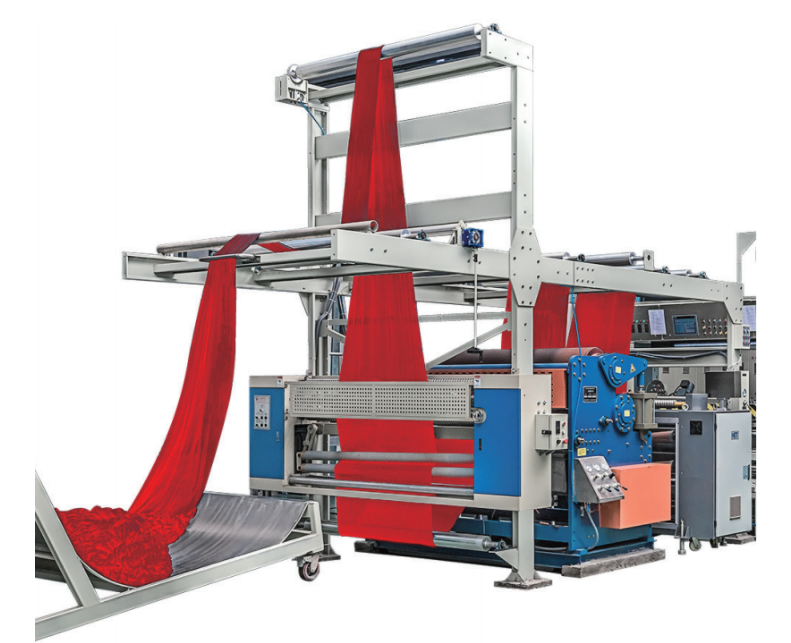

Textile Fabric Finishing Process

Textile fabric post finishing is a technical treatment method that imparts color effect, morphological effect (smooth, suede, starching, etc.) and practical effect (impermeable, non-felting, non-ironing, non-moth, flame resistance, etc.) to the fabric. Post finishing is a process that improves th...Read more

Leave Your Message:

Write your message here and send it to us.